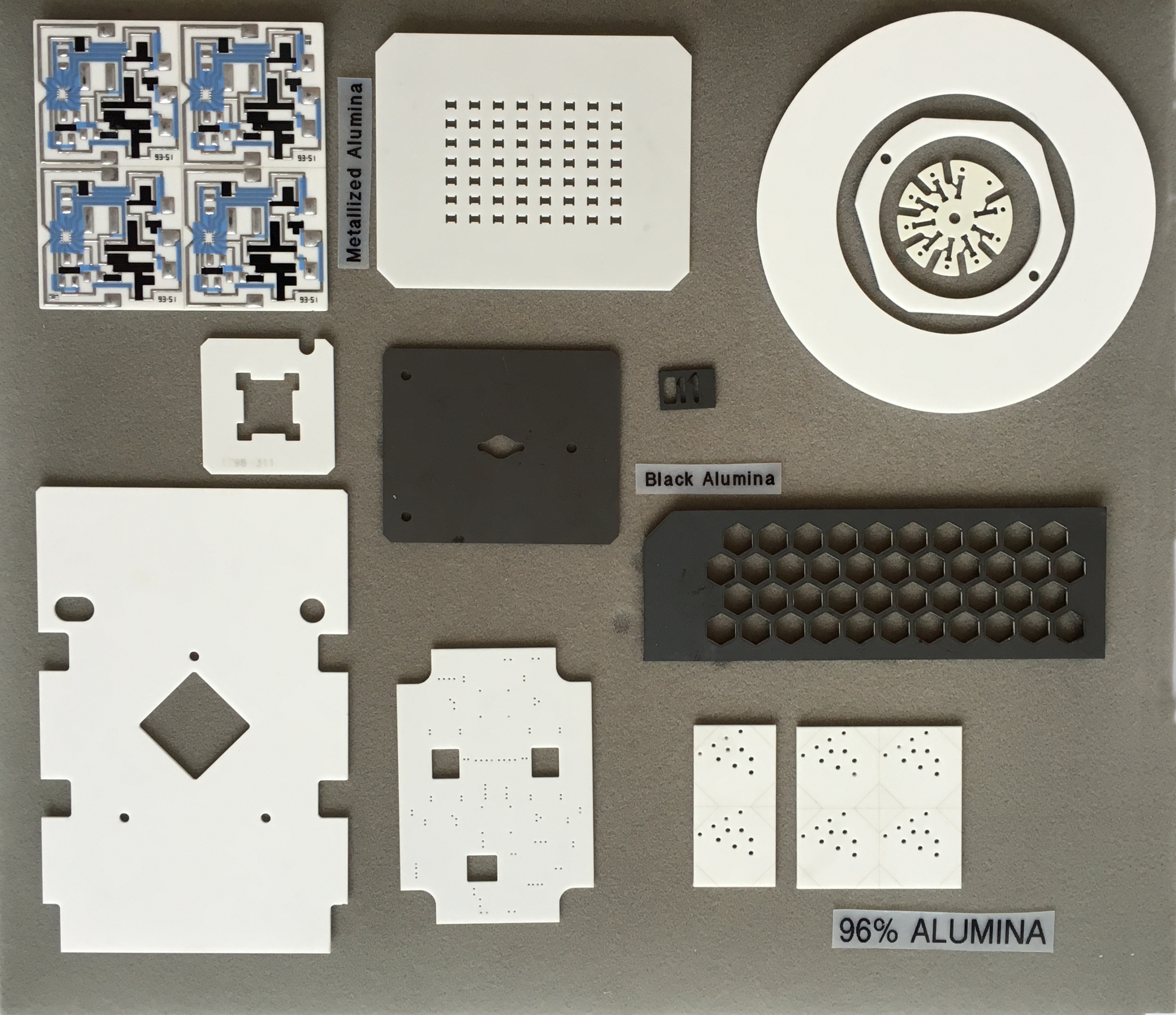

Substrate materials size thickness laser machining laser scribing edge finishing design guides coorstek developed the standards for thick film ceramic substrates and continues to provide economical yet durable substrates for hybrid integrated circuits surface mount devices sensors and other thick film electronics.

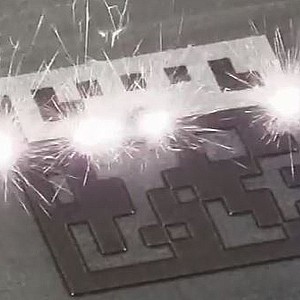

Laser scribing ceramic substrates.

Ceramic substrate electronic circuit carriers or supporting laser machining ceramic substrate leatec have excellent laser service for al2o3 aln substrate.

The process involves pulsing a co2 laser through an optical configuration through a focusing lens focusing the beam through an air assisted nozzle assembly and finally onto the substrate s work surface.

View pdf view pdf in german scribing and micromachining of aln and al2o3 ceramics has been dominated by the use of co2 lasers for 30 years the simple reason being that the 10 6 μm wavelength has been the best suited to processing these types of materials.

System can be equipped with co2 laser and innovative fiber laser for better precision and higher edge quality.

That is because more power is required to com.

Laser cutting takes longer than scribing because the laser is cutting com pletely through the substrate which likely also increases fabrication cost.

What is laser scribing.

As opposed to laser cutting the laser beam does not go all the way through the material during a laser scribing process and the goal is to make a perforated line along which an easy and clean break out can be done.

Als200 is a very high accuracy laser system that is designed for scribing drilling and cutting of ceramic substrates for thin and thick film hybrid circuits up to 6 x6 typical al 2 o 3 and aln.

Laser processing service for ceramic substrate 1 laser cutting scribing and drilling service for ceramic substrate.

Laser scribing is drilling a series of blind holes in a line to create a weak spot in the material and ensure a clean cut when breaking out.

2 leatec provide the design laser express and surface treatment consultation service.

This is the best way to ensure precise and clean milling and drilling of the ceramic.

Selection depends on ceramic type economical advantages for users.

How are the ceramic substrates machined.

Substrate materials size thickness lapping polishing laser machining scribing annealing coorstek is the leader in custom and standard thin film ceramic substrates.

Nevertheless feature size and finish quality of the ceramic substrates used for electronics applications.

Yield i e the number of parts that come from a single ceramic sheet is also lower with cutting.

Remote internet monitoring and.

Laser scribing is a technique that allows for easy singulation of ceramic substrates circuits from a manufacturing panel sheet.

One for cutting and one for scribing als200 lasers are offered as basic system with manual loading unloading or with.

Four thin film substrate material options combine smooth surface finish strong flexural strength and consistent electrical properties.

The system is equipped with double nozzle for an e automatic switching.